Contact Lens Manufacturing Technology

Contact lens production technology:

Contact lens technology first gained popularity in South Korea, focusing on yearly replacement and customization. Therefore, early colored contact lenses mainly utilized cutting processes. Due to the mass production requirements for disposable lenses, the majority now adopt fully automated molding methods. Currently, molding technology is the mainstream for producing short-cycle disposable lenses, effectively reducing the cost per lens.

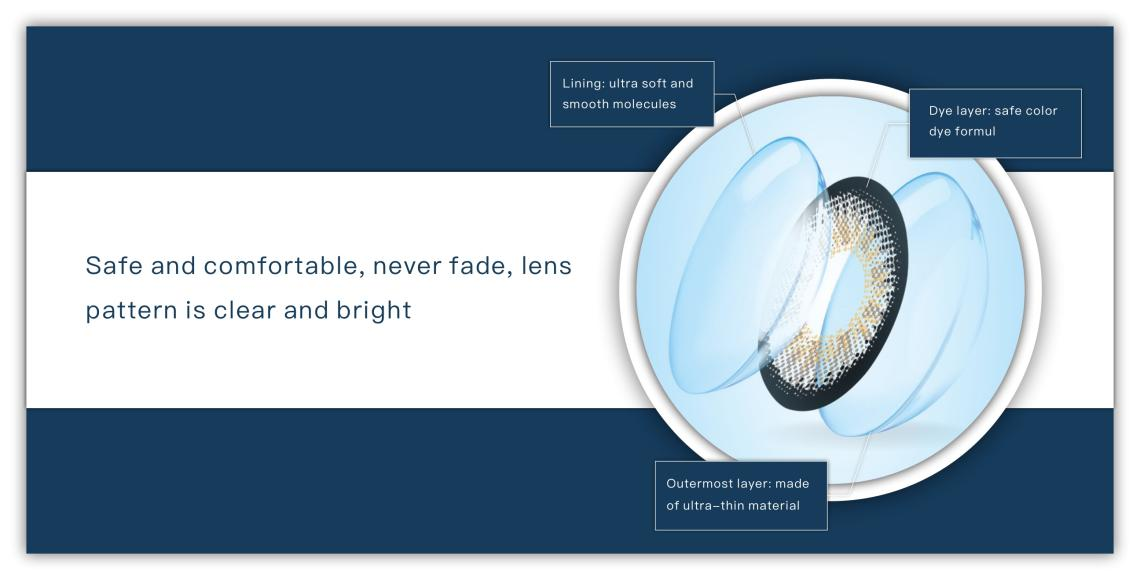

Both colored contact lenses and regular disposable lenses primarily use molding processes, with the main difference being the inclusion of a "color layer" in colored contact lens products. Contact lenses directly contact the cornea and conjunctiva, and if the color pigments in colored contact lenses directly touch the cornea and conjunctiva, it can cause mechanical irritation. Additionally, pigments on the lens surface can affect smoothness, causing a foreign body sensation and potentially leading to bacterial retention and infection.

Colored contact lenses require pigments with sufficient stability and safety to ensure pigments do not detach from the lens and enter ocular tissues. Therefore, brands like Menicon often employ a technique known as "Sandwich Technology," embedding the color layer between lens layers to avoid direct contact with the eyes.

Colored contact lenses can change pupil color and enlarge pupil size, enhancing the wearer's appearance, and are highly favored by the younger consumer demographic. Approximately 77.4% of colored contact lens consumers maintain a weekly habit, with 41.9% using them for 7-8 hours daily. Due to prolonged wear, consumers prefer medium-term colored contact lens products (76.7%), and over 66.0% are willing to spend $501-1000 annually on such products.

Currently, Japan and South Korea have a contact lens penetration rate exceeding 20%, while Europe and the United States generally exceed 40%. In contrast, China's contact lens penetration rate is only 7.5%.

Post time: May-25-2022